Sporeformers are certain bacteria which can transform themselves from vegetative (= growing) form to spores (= resting form). Best-known examples of these bacteria are aerobic sporeformers ("bacillus-type", inc. Bacillus sp. , Paenibacillus sp. and other Gram-positive, aerobic sporeformers) and anaerobic sporeformers (most common species belong to the genus Clostridium). These bacteria are very common in all environments, especially in soils.

Spores of bacteria are not intended in the reproduction of organisms (like fungal spores) but to keep bacteria alive in conditions where they cannot be metabolically active. Sporulation is caused by the lack of nutrients, and germination of spores takes place whenever environmental conditions turn better for the growth of the bacterial cells.

These bacteria are a problem for paper industry because their spores tolerate dryness, cleaning agents and biocides very well. Their main sources are mineral pigments and starches, especially when these raw materials are delivered to the mills as dry powders. Whenever they are slurried, an effective biocide program shall be applied in the total system of their storage and dosing into the machines.

Another problems are analytical ones. Spores can be detected after a simple pasteurization of the samples (vegetative cells get killed, only spores stay alive) but this procedure kills also vegetative sporeformes. An analysis called "Sporeforming bacteria" does therefore not show potential sporeformers which are in vegetative growth phase. In addition, germination of spores, like every other chances in the properties of bacteria, takes certain time. This slows the growth of spores on nutrient media significantly. Fastest germination times can be achieved by PMEU incubator but the outgrowth of spores into vegetative cells may take much longer periods on the agar plates.

Evaluation of biocides should also be done with equipments like PMEU which show the different effects of biocides in the original samples.

Last but not least: if the growth of certain aerobic sporeformers has been very active, starch-degrading enzymes can stay active after biocidic treatments. Amylases can be found even after heat treatments because many of them are thermotolerant ones.

Sporeforming bacteria of paper industry have been studied very actively in Helsinki University, Dep. of Applied Chemistry and Microbiology. IM recommends to read scientific articles, written by the research group of Professor Mirja Salkinoja-Salonen, in magazines like "Applied and Environmental Microbiology" and "Industrial Microbiology and Biotechnology".

This group of bacteria is always a target of HACCP activities of paper mills, especially when products with high hygiene quality are manufactured. Studies to understand their features is therefore continuing also in future.

Saturday, July 12, 2008

Monday, July 7, 2008

Concepts of microbial ecology and biotechnology in process industry.

Coming back to the issues of microbial ecology and biotechnology:

Both of them have helped IM to understand the multitude of microbial activities which are typical for paper industry. Technical framework, beginning from the preparation of raw materials and ending to the waste water treatment plants can be regarded as fermentors or bioreactors where growth conditions vary a lot. Everlasting input of bacteria (and sometimes also fungal organisms) contain strains which can be adapted into these processes and live in them over very long periods - even tens of years. These topics, definitely, belong also to the research area of microbial ecology and its theories about adaptation, competition, synergisms...

These issues have been discussed by IM already in previous posts and shall be taken into account - in more detailled form - in near future.

By the way - what would be more interesting than to have shared net forum of paper industry engineers, environmental microbiologists, ecologists, biotechnicians and other specialists to discuss about similarities and analogies between natural environments and paper mills? Even limnology gives hints to understand certain microbial activities - like the growth of microbes in water flows as biofilm organisms. Another analogy can be found when observing the microbial populations of lake or ocean sediments and the microbial flora of different kind of depositions in paper mill machinery.

IM is looking forward to hear various multiscience views by biologists, biotechnical and environmental microbiologists, ecologists, limnologists and oceanologists about similarities between natural environments and paper machines!

Both of them have helped IM to understand the multitude of microbial activities which are typical for paper industry. Technical framework, beginning from the preparation of raw materials and ending to the waste water treatment plants can be regarded as fermentors or bioreactors where growth conditions vary a lot. Everlasting input of bacteria (and sometimes also fungal organisms) contain strains which can be adapted into these processes and live in them over very long periods - even tens of years. These topics, definitely, belong also to the research area of microbial ecology and its theories about adaptation, competition, synergisms...

These issues have been discussed by IM already in previous posts and shall be taken into account - in more detailled form - in near future.

By the way - what would be more interesting than to have shared net forum of paper industry engineers, environmental microbiologists, ecologists, biotechnicians and other specialists to discuss about similarities and analogies between natural environments and paper mills? Even limnology gives hints to understand certain microbial activities - like the growth of microbes in water flows as biofilm organisms. Another analogy can be found when observing the microbial populations of lake or ocean sediments and the microbial flora of different kind of depositions in paper mill machinery.

IM is looking forward to hear various multiscience views by biologists, biotechnical and environmental microbiologists, ecologists, limnologists and oceanologists about similarities between natural environments and paper machines!

Sunday, July 6, 2008

Why shall paper industry be moved to foreign countries from Finland?

IM was sitting with an old friend from Helsinki on the terrace of his summer cottage (no water lines, no electricity)on yesterday evening.

- (IM) Where are we going in near future?

- Basic production (agriculture, fishing etc.) will be respected after a while...

- Why we cannot continue P&P production in Finland?

- Labour costs are not the problem. Their share is under 10% of the costs of paper production.

- But..?

- Transport of the products and price of the raw material are the main problems.

IM has read from local newspaper "KESKISUOMALAINEN" about the problems of timber production. A manager of timber enterprise told that "the taxes are the problem. Price of the Finnish raw wood is too high today. Government should help to have wood with acceptable prices..".

This is economy.

- (IM) Where are we going in near future?

- Basic production (agriculture, fishing etc.) will be respected after a while...

- Why we cannot continue P&P production in Finland?

- Labour costs are not the problem. Their share is under 10% of the costs of paper production.

- But..?

- Transport of the products and price of the raw material are the main problems.

IM has read from local newspaper "KESKISUOMALAINEN" about the problems of timber production. A manager of timber enterprise told that "the taxes are the problem. Price of the Finnish raw wood is too high today. Government should help to have wood with acceptable prices..".

This is economy.

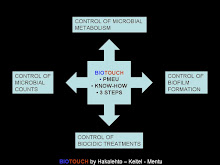

Microbiology shall be taken as an important issue in paper production.

IM will thank Dr. Elias Hakalehto about his valuable comments!

It seems that there is only one industrial environment where the intense growth of harmful bacteria is allowed: paper and board production.

This is caused by the need of huge amounts of water inside paper mills. This water is carrying valuable raw materials and (despite the frequent questions by IM) the most spoiled water fractions will not be delivered to waste water treatment. The spare of water has led to (microbiologically) insane solutions like the use of certain white water fractions in spray water system of wire section. Every microbiologist knows what happens...

There are several microbiological threats in paper industry:

* spoilage of raw materials

* biofilm and slime problems of the machines

* defects of product hygiene

* health risks

Production of paper without water was discussed at 80's. It does not work. Connection of fibres in wire section has failed. Water is needed to form a network of fibres, strong enough to "jump" to pressing section. It is an impressive event: still having tens of percents water, paper will go independently over a gap between wire and pressing rolls, without any support...

Water is needed in paper machines, no doubt. But how to control its microbiological quality?

Harmful bacteria can (which IM has experienced) be detected with rapid methods like PMEU, ATP Assay and PCR. It is the question of (economical) resources if it will be done.

It seems that there is only one industrial environment where the intense growth of harmful bacteria is allowed: paper and board production.

This is caused by the need of huge amounts of water inside paper mills. This water is carrying valuable raw materials and (despite the frequent questions by IM) the most spoiled water fractions will not be delivered to waste water treatment. The spare of water has led to (microbiologically) insane solutions like the use of certain white water fractions in spray water system of wire section. Every microbiologist knows what happens...

There are several microbiological threats in paper industry:

* spoilage of raw materials

* biofilm and slime problems of the machines

* defects of product hygiene

* health risks

Production of paper without water was discussed at 80's. It does not work. Connection of fibres in wire section has failed. Water is needed to form a network of fibres, strong enough to "jump" to pressing section. It is an impressive event: still having tens of percents water, paper will go independently over a gap between wire and pressing rolls, without any support...

Water is needed in paper machines, no doubt. But how to control its microbiological quality?

Harmful bacteria can (which IM has experienced) be detected with rapid methods like PMEU, ATP Assay and PCR. It is the question of (economical) resources if it will be done.

Subscribe to:

Posts (Atom)