IM is wondering: are there any other sector of process industry, where microbes are allowed to grow like in paper industry?

Biotechnological processes, of course. But their populations are carefully selected and controlled. And they are employers of the company, not criminals trying to cause harm to the company.

Some significant changes in paper industry processes have taken place after the rise of active environmental care. Both the

closure of water circulation and the cancelling of biocides having

mercury as an active incredient are favorable for the environment, of course. But the microbial growth inside the paper machines has activated at the same time.

The beginning of

neutral paper production led to an "ecocatastrophe" inside paper machines. The rise of pH value (as well as the rise of temperature, caused by the extended recirculation of water) was fatal for slow, acid-loving fungal growth. New

mineral additives are an important source of certain types of bacteria, causing severe problems like production of slime, spoiling of the process compounds and hygiene faults of the products.

IM has published an article

"Paper Machine: an Ecosystem and a Bioreactor" (INOCULA 1/2007. Helsinki, Finland). Many readers agree: paper machines offer ecological niches for bacteria, and the controlled environments of wet end circulations are very much similar with those of biotechnical processes, based on chemostatic fermentors.

A lot could be do to make paper machines more unfavorable growth environment for microbial contaminants. Very good results have been achieved in some projects where ecological aspects have been taken into account. These issues will be discussed later in this blog.

But the main question is:

how much biocides we still need to control the microbial growth in all regions of a paper machine?

Incoming raw materials, sorry to say, may be very contaminated: the highest value of total count during IM's career has been over 100 000 000 cfu/g in a mineral slurry (which was fortunately replaced by a fresh lot by the supplier!). It is therefore obvious that a

continuous control - both analytical and practical - is needed for starches, mineral pigments and other contaminated raw materials. This does not mean that all lots are spoiled: there are suppliers which know their response to deliver pure products to the mills but all kind of errors in biocidic pre-treatment, transport and storage of these products may happen.

Certain sites of paper machines also need biocidic treatments all the time. Chosing proper solutions for

biocide programs (type of biocide, active compound, dosing sites, timing etc.) of a paper machine is a challenging tasks. In best cases, both the paper mill and biocide personnel are sitting down and discussing of the individual problems of the paper process hygiene.

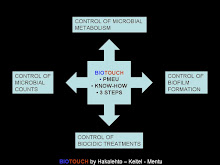

When specified laboratory services, having tools like PMEU and biofilm microscopy, are included, the final result can be optimal one. Paper industry microbiologists can also help significantly by declaring the effects of process parameters on the growth of planktonic and biofilm bacteria.

The more competence is included, the better solution will be find.